Metal roofs are a popular choice for homeowners because of their durability, energy efficiency, and modern look. But sometimes, you might notice subtle ripples or waviness across the flat sections of a roof. This effect is known as oil canning. While it can catch your eye, it’s important to know that it’s a cosmetic issue and doesn’t affect the performance of your roof.

What Oil Canning Looks Like

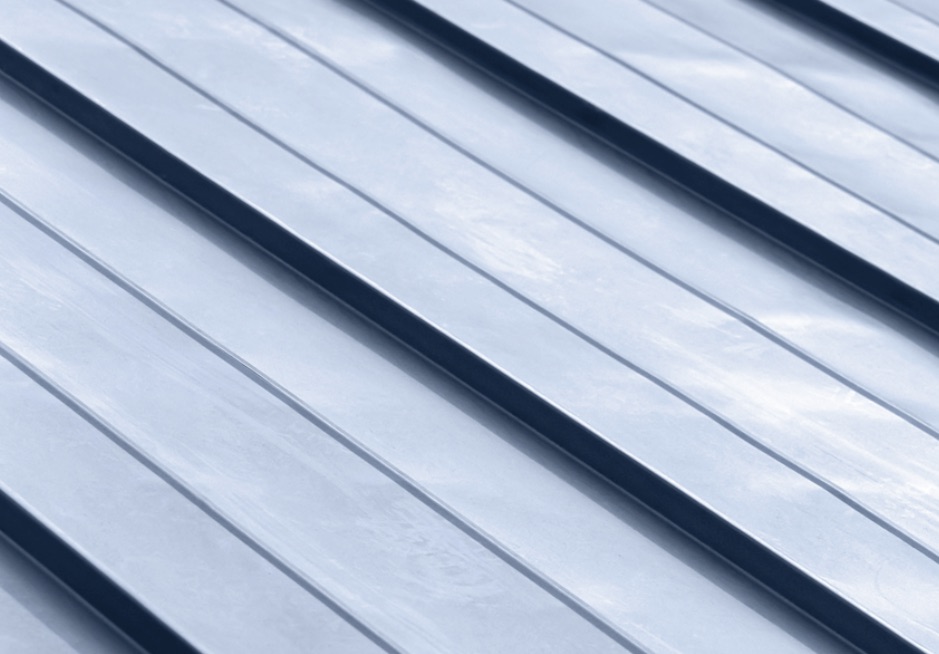

Oil canning is a visual effect that causes flat areas of metal panels to appear slightly wavy or lined. It’s most noticeable in panels with wide, uninterrupted surfaces or glossy finishes, and it can often be seen only from certain angles or in direct sunlight. In the industry, it’s also called stress wrinkling or elastic buckling.

Although it may be noticeable, oil canning is not a structural issue. There is no standardized method for measuring it, and it does not reduce the roof’s functionality. It is a naturally occurring condition, and industry standards state that oil canning is not a defect and not a reason for rejection.

Why It Happens

Oil canning is caused by internal stresses in the metal, which can develop at multiple stages:

- Manufacturing: Metal panels are rolled and shaped under pressure. Any small inconsistencies during production can leave stress in the material.

- Roof Structure: Uneven decking, structural shifts, or subtle imperfections in the roof substrate can contribute to waviness.

- Installation: Twisting, bending, or overtightening fasteners during installation can add stress.

- Temperature Changes: Metal expands and contracts with heat and cold. If movement is restricted, internal pressure builds, which can create visible ripples.

Even small movements can produce noticeable effects. That’s why oil canning is considered a natural characteristic of metal panels rather than a flaw.

How to Minimize Oil Canning

While oil canning cannot always be fully prevented, several strategies can minimize its occurrence:

- Choose Thicker Panels: Heavier gauge metal is less prone to waviness.

- Panel Design Matters: Striated or ribbed panels help break up large flat areas and add rigidity.

- Stress Relief Techniques: Using a backer rod along the center of a panel can help relieve internal stress.

- Careful Installation: Avoid twisting panels and over-tightening fasteners. Ensure fastening systems allow for natural expansion and contraction.

Even with careful planning, oil canning may still occur, especially if caused by underlying structural or substrate conditions. Replacing panels alone may not always solve the problem.

Conclusion

Oil canning is a natural, cosmetic phenomenon in metal roofing. It doesn’t compromise the roof’s durability or performance, and it’s widely accepted in the industry. Choosing the right materials, using thoughtful panel designs, and working with experienced installers can help reduce the likelihood and visibility of oil canning

At Gulf Coast Supply, we help homeowners and contractors select quality metal roofing solutions that combine performance and aesthetic appeal—while understanding and managing natural effects like oil canning.